Project Case |

| The company has built many successful cases of Intelligent Manufacturing in digital factory, mechanical equipment manufacturing industry, metal processing industry and auto parts industry, which have been delivered to customers and implemented on customers' site. |

|

The company has built many successful cases of Intelligent Manufacturing in unmanned digital factory, mechanical equipment manufacturing industry, metal processing industry and auto parts industry, which have been delivered to customers and implemented on customers' site. |

|

Black light factory of large household appliance listed company |

The transformation and upgrading of a listed electrical company has gone through a long decade. At the beginning of the production workshop just entered the era of "digital equipment", the equipment began to set some parameters and generate data automatically, and the data, people and equipment only had preliminary interaction. Five years ago, although it entered the acceleration period of intelligent manufacturing, there was no seamless connection between systems, and different business data could not be connected independently. Until 2020, when the "black light factory" is fully completed

Solution:

With a total investment of nearly 500 million yuan, the company will build an unmanned factory covering an area of about 50000 square meters in 2020 with digital, networked and intelligent transformation as the main line.

The reason why it is called "black light factory" is that the entire stamping workshop of tens of thousands of square meters is in the "black light" state. Only the equipment status indicator light, quality inspection light and laser transmitter are flashing. Through the mobile 5g network technology, the workshop production equipment parameters are all connected to the industrial Internet platform, from online and offline orders received to the factory delivery, the whole line is opened up, and the materials at all points of "black light factory" have realized self mainstream transfer and automatic warning. On the basis of the original intelligent manufacturing, "black lamp factory" product development cycle is shortened by 48%, production cost is reduced by 21%, operation cost is reduced by 15%, production efficiency is increased by 45%, and "cost reduction and efficiency increase" is realized. |

|

|

|

Influencer Liziqi have a famous snail powder processing factory,its monthly sales have exceeded 1.5 million. The increasing orders have doubled the recruitment of the workers of this manufacturer in a short time, and a large number of product quality problems have been exposed.

Influencer Liziqi has set up a wholly-owned food subsidiary and built a digital intelligent production factory in Liuzhou, making it a leading domestic and international e-commerce platform integrating live broadcast, brand, sales, e-commerce, production and delivery.

Solution:

Considering the purpose of establishing the snail powder production plant, the intelligent management and control system of the plant should first meet the needs of production, so that the newly developed formula can be put into production quickly, changing the situation of only one formula. Second, it should have supply chain management system, incoming quality inspection system and processing quality inspection system, and cooperate with the quality assurance system established by the factory to realize quality traceability and raw material quality control.

Considering the characteristics of online Red sales, it should have the functions of docking with live broadcast platform, online e-commerce and network production process display, with high intelligent and visual ability. |

|

Influencer intelligent factory |

|

|

CNC machining center project |

Every time the automatic machine tool on the customer's site is processed, workers need to manually load and unload materials, and manually set processing parameters / processes. There are tens of thousands of parts to be processed on the customer's site, which leads to very high requirements for workers; In addition, due to different operators, the input processing parameters are also different, resulting in the quality of processed parts can not be guaranteed.

Solution:

The company has designed the automation software of "machine tool loading and unloading" and "machine tool operation" to help customers realize automatic loading and unloading by using cooperative robot, and directly control the machine tool through "machine tool operation software".

The utilization rate of machine tool is 97.79%; The monthly production benefit of single equipment increased from - 6.11% to 2.4 times; Realize the whole process traceability of single product processing; Effectively improve processing efficiency and product quality. |

|

|

|

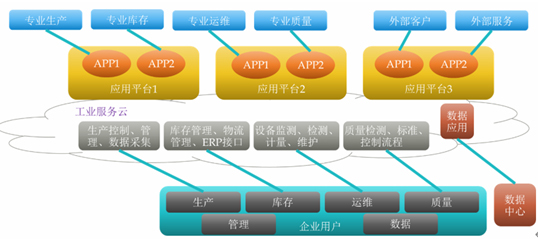

The purpose of customer building three clouds is to promote the implementation process of industry 4.0 in China, do a good job in the transformation and promotion of intelligent manufacturing technology, and promote and help the intelligent transformation of Chinese manufacturing enterprises. Therefore, the construction goal of three clouds should be to establish a basic platform to support diversified applications of multiple enterprises, based on the convenience of rapid application of enterprises, to help enterprises use intelligent technology to reduce costs and improve productivity.

Solution:

The company helped customers sort out the construction objectives, business needs and technology application needs of the three cloud platforms. The construction objectives of the three clouds are clearly defined: the three clouds can provide different types of services for different enterprises, enable system integrators, carry and provide services and applications for different enterprises / colleges / research units, provide online services / offline services, and share online and offline services.

The company helped customers define the design objectives of phase I of three clouds, that is, to display the latest achievements of customized intelligent manufacturing and the latest applications of three clouds. The basic definition and specific functions of the three clouds (innovation cloud, intelligent manufacturing cloud and industrial service cloud) are given to help customers complete the planning of the basic platform architecture of the three clouds. The scheme of the consulting project is highly recognized by customers. |

|

Three cloud consulting projects of a large-scale intelligent manufacturing center in Shanghai |

|

|

|